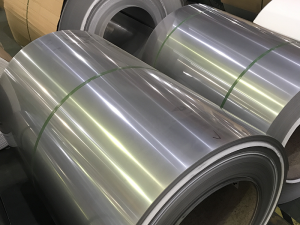

410S Stainless Steel Coil

Description

Famaritana:

1. Fenitra: ASTM A240, JIS G4304, EN10088

2. Grade: 200-andian-dahatsoratra & 300-andian-dahatsoratra & 400andian-dahatsoratra

3. Hatevina: 0.03mm - 6.0mm

4. sakany: 8mm-600mm

5. Length: araka ny fangatahan'ny mpanjifa

6. Surface: 2D,2B, BA, Mirror vita, N04, Hair Line, Matt finish, 6K, 8K

7.Technology: mangatsiaka voasintona / mangatsiaka nanakodia / mafana nanakodia

Akora:

| Type | kilasy | kilasy | singa simika% | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Hafa | |||

| Austenitic | 201 | SUS201 | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50–7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | SUS202 | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1.4310 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1.4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304L | 1.4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1.4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316Ti | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1.4550 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| Duplex | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0.030 | ≤0.020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0.035 | ≤0.020 | 3.0-5.0 | ≤0.80 | 0.5 | 0.24-0.32 | ||

| Ferrite | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Cr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0.025 | 17.50-19.50 | 1 | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2.5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 | |

| Martensite | 410 | 1Cr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0.080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | ≤0.50 | - | Al 0.75-1.50 | |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0.040 | ≤0.030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0.75-1.50 | |

Fampahalalana fototra

410s Stainless Steel Coil, miaraka amin'ny fanoherana ny harafesina tsara sy ny machinability, dia vy tanjona ankapobeny sy vy fitaovana fanapahana.410S dia karazana vy izay afaka manatsara ny harafesiny fanoherana sy ny formability ny 410 vy.410S dia tanjaka ambony vy izay afaka manatsara kokoa ny harafesiny fanoherana ny 410 vy.Izy io dia ampiasaina amin'ny lelan'ny turbine sy ny ampahany amin'ny hafanana ambony.

• Famaritana: AISI 410s, ASTM 410s

• Famaranana: Ba surface, 2b surface, No.1 (fotsy hoditra), 2D surface, No.4 (frosted), HL (wire drawing), 8K surface manana kalitao ambony indrindra

•Mihatra ny fandeferana ny fikosoham-bary amin'ny hateviny sy ny fisakany. Antsoy ny JM Steel raha mila habe manokana na tari-dalana ianao.

410S teknolojia machining toetra

1D -- Ny habakabaka dia manana endrika granular tsy miovaova, fantatra amin'ny anarana hoe zavona.

Teknolojia fanodinana: fanodinkodinana mafana + fanodinkodinana fitifirana fanangonam-bokatra + fanodinkodinana mangatsiaka + fanangonam-bokatra.

2D - Loko fotsy somary volafotsy.

Teknolojia fanodinana: fanodinkodinana mafana + fanodinkodinana fitifirana fanangonam-bokatra + fanodinkodinana mangatsiaka + fanangonam-bokatra.

2B - Fotsy volafotsy manana famirapiratana sy fisaka tsara kokoa noho ny 2D.

Teknolojia fanodinana: fanodinkodinana mafana + fanodinkodinana fitifirana peening pickling + fanodinkodinana mangatsiaka + fanodinkodinana annealing + fanodinkodinana sy fandoroana.

Ba - Famirapiratana tsara tarehy, tara-pahazavana avo, toy ny fitaratra.

Teknolojia fanodinana: fanodinkodinana mafana + fanodinkodinana tifitra peening pickling + fanodinkodinana mangatsiaka + fanodinkodinana annealing + famolahana ambonin'ny + fandoroana sy fanodikodinana.

No.3 -- Manjelanjelatra tsara, ambonin'ny voamadinika.

Teknolojia fanodinana: fanosehana sy fanodinkodinana ho an'ny 2D na 2B miaraka amin'ny fitaovana abrasive 100 ~ 120 (JIS R6002).

No.4 -- Manjelanjelatra tsara, tsipika tsara amin'ny endriny.

Processing dingana: polishing sy tempering rolling ho 2D na 2B amin'ny 150 ~ 180 abrasive fitaovana (JIS R6002).

HL -- Volafotsy miloko volom-bolo.

Teknolojia fanodinana: Ny vokatra 2D na ny vokatra 2B miaraka amin'ny granularity mety amin'ny akora abrasive ho an'ny famolahana ny tany dia voam-bary tsy mitsahatra.

MIRRO -- Specular.

Teknolojia fanodinana: vokatra 2D na vokatra 2B miaraka amin'ny granularity mety amin'ny fikosoham-bary mikoriana sy manosihosy amin'ny vokatry ny fitaratra.